Product Introduction

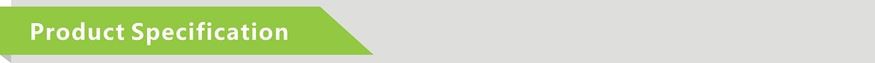

Container homes now becomes one way of affordable, comfortable and efficient living. Single container design including: bedroom, living room and bathroom. Also could stack several containers to get a bigger house, then you could have kitchen, activity room, dining room, bathroom and balcony.

What processes are required to make a container house?

People who are considering building a container house must be curious about the manufacturing process of a container house and want to do it themselves. Making a container house requires us to do several relatively simple processes in the early stage.

1. Planning: The first step in building a container house is planning. We need to work out the design, budget and other necessary details before we start building. The first and most important thing is to determine the size, number of rooms and location of the container house.

2. Choose a container: After planning, the next step is to choose the right container. Containers used to build container homes are generally made of steel or aluminum. These materials are very durable and can withstand harsh weather conditions. It is important to make sure that the container is in good condition and does not have any issues with rust or holes.

3. Site preparation: Organize the location where the container house will be placed. All trees or vegetation will need to be cleared, the ground leveled, and the foundation prepared. The foundation is especially important as it will support the weight of the container home. Container houses usually use concrete as their foundation. This again involves the question of how and how much concrete needs to be laid.

4. Design Modifications: Once the container is delivered, the design can be modified to suit your needs. The design needs to consider issues such as practicality and aesthetics. The exterior design needs to be beautiful, and the internal space configuration needs to consider practicality.

5. Plumbing and electrical work are also part of the container design. Before the walls are installed, pipes and wiring need to be secured inside the container house and all necessary fixtures, wiring and sockets installed. This requires the services of a professional plumber and electrician.

6. Finishing touches: Once the plumbing and electrical work is complete, it's time to add the finishing touches. This includes painting the exterior and interior, floors and furniture. This part can be based on the customer's personal preferences.

Does a container house need a foundation?

The foundation provides a secure base for the container and helps distribute its weight evenly to the ground. It helps to prevent the container from sinking into the ground or shifting in high winds or earthquakes. A good foundation also provides insulation and protection from dampness, moisture, and other weather-related conditions.

There are different types of foundations that can be used for container houses, depending on the climate, location, and soil type. These include concrete slabs, concrete piers, steel posts, and crawl spaces. The type of foundation used can also affect the cost and time involved in building the container house.

container office canada

Container House France

Container office converted from shipping containers

Container house manufacturer

Size | 20ft/40ft/40HQ |

5.8*2.2*2.5m; 11.8*2.2*2.5m | |

Color | Black |

Loading | Sea container design can be shipping as ISO container |

Prefab container design need loading into sea container to ship | |

Structure | Steel base: Q235; hot galvanized steel |

Column: Q235; hot galvanized steel | |

Steel corner with hole: Q235; hot galvanized steel | |

Roof system: Q235; hot galvanized steel | |

Wall | Exterior wall: waved steel panel; original sea container wall |

Insulation layer: glass wool; rock wool; XPS ;PU spray | |

Interior wall: bamboo fiber board; plywood; pine wood | |

Roof | Exterior roof: waved steel panel; original sea container roof |

Insulation layer: glass wool; rock wool; XPS ; PU spray | |

Interior wall: bamboo fiber board; plywood; pine wood | |

Floor | Indoor floor: PVC floor; |

Middle layer: calcium silicate; | |

Bottom frame: hot galvanized steel | |

Window | Retractable windows |

Size:as requested | |

Door | Aluminum door |

External size:as requested | |

Electrical system | 1 electrical distribution; 2 industrial plug; 2 lights;2switches;3 sock ets (with A/C socket); electrical wire |

Temperature | suitable temperature.-50°C~+50°C |

Others | Furniture and appliance are customized-made to your requirements(additional cost) |

Floor load | 0.5KN/square meter |

Roof load | 1.5KN/square meter |

Wind resistance | Grade 11(wind speeds111.5km/h) |

Container houses are widely used and are not affected by the environment and the region, such as: temporary shelters for construction workers common on construction sites; shelters on the front line of disaster relief; professional custom-made home stays, restaurants, and bars; rest for outdoor exploration projects ground.

Advantages of container houses:

Easy to movable anywhere as you want.

Container houses can be changed without changing houses. When you need to change places, you can find a moving company (or a large truck or trailer) to move the container directly to the designated place, and you can save the trouble of finding, buying, and decorating.

Easy installation. Generally, the mobile housing of a container is an independent whole and can only be hoisted. It has already been installed at the factory. At the scene, it is installed with water and electricity. This should not fall into the scope of installation. It is safe and reliable. It's suitable for for a magnitude 10 earthquake,because the structure are all-steel structure.

This container home size it is 5.8*2.2*2.5m, inside could supply with bathroom, bedroom.

Loading as SOC container or loading into 40HQ container to ship.

1.What is the average cost of a shipping container home?

The price of container homes varies widely depending on a number of factors, from home size and number of containers used to location and materials used in and outside of the home. It also depends on if you are building the home custom or buying prefabricated. In general, though, these homes tend to fall between $8,000-$38,000 for a single container model and $16,000 to $76,000 for a multi-container house. Don't forget to factor in the cost of land and labor to your overall budget!

2.Are container homes safe?

Shipping containers are as safe and reliable as traditional homes. We all know that shipping containers can transport many different types of goods over long distances and need to go through many bumpy roads. This is a strict test for shipping containers and ensures that the goods can reach the customer unscathed. This also fully demonstrates the safety and reliability of shipping containers. They can withstand many tests such as weather and natural disasters, so container houses transformed from shipping containers are also safe and reliable.

3. How do you insulate container homes?

I believe many people will be concerned about how containers can be used normally in cold or hot weather, which involves the issue of thermal insulation. Generally, we will use two methods to solve this problem: one is external construction and the other is internal construction. Internal construction is to separate the internal wall from the external wall by a certain distance, which can ensure heat insulation and reduce noise impact. But the disadvantage is that it takes up internal space. Another way to build outside is to fill the corrugated panels of the exterior wall with foam or insulation cotton and then paste them with decorative materials. This approach can make the outside of the container house more beautiful while ensuring heat insulation.

Hot Tags: Multi Units Container House, manufacturers, customized, quotation, made in China, Container residential apartment, Black double decker stacked container hotel, Self built shipping container hotel, Container Hotel renderings, Wooden container house, Transform the container house made of containers